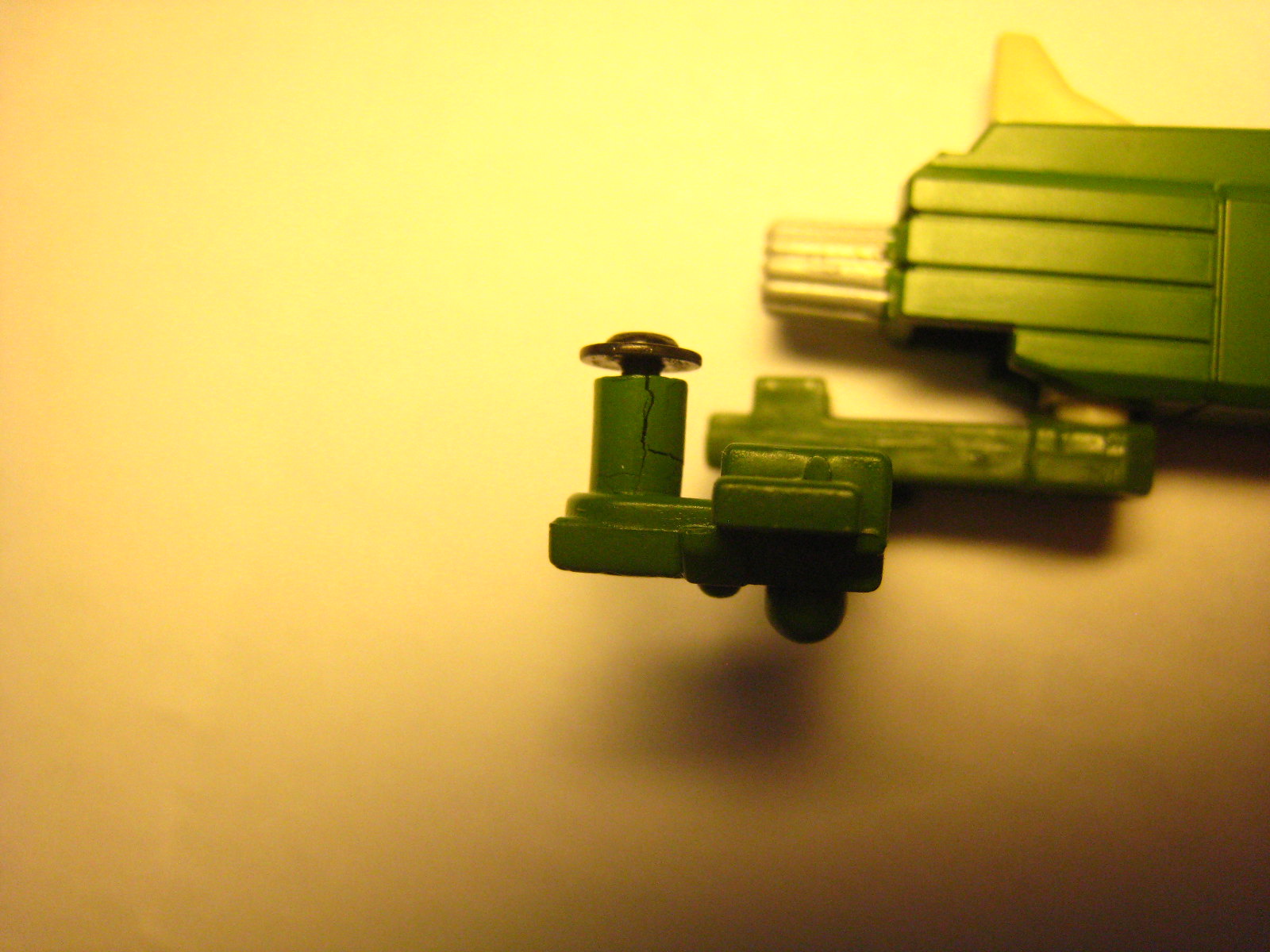

I removed the screw at the armature. I used a JIS screwdriver but the screw came out easily and I perhaps could have just used a regular Philips head. Perhaps the reason the screw came out easily is due to the post being cracked as shown in the pics. Also one thing I've noticed for a while is that a bit of oil has been seeping from that armature joint. I guess that's an oil they used at the factory. I don't think it's coming from the plastic itself. The pressure of the screw opens the crack more, so the plastic quality is poor or the screw/hole size is badly engineered or both. As you can see, the peg cracks are like a network so it's a matter of time before the whole thing fractures into tiny bits. Some people have filed down the peg to solve the problem of the outside ring of that joint from cracking. But since the screw is cracking the peg, sanding the peg won't fix that, and could even increase the chance of peg cracking. The only way to fix this that I can see is to fill the screw hole (and cracks) and redrill it. Without some fix, I'm certain transformation will completely break it. And it's only been transformed from new in box car to robot. Such a shame for such an expensive figure.

Reply With Quote

Reply With Quote