I'd be keen for an Autobot faction logo for sure!

I'd be keen for an Autobot faction logo for sure!

Good point. I was assuming the bulk stuff would be pretty good. But if I've given my ones enough sealed layers, they should last quite a while... hmm- which I had a time machine to test my theory! XDD

I'll give that a try. The issue is cutting this paper is REALLY difficult (if if your corners are too sharp, they can crack in the oven). But I will still give it a shot!

I'll make some then! See how they turn out~ ; )

I would also be interested in some of your starscream stuff as my better half would like it.

the torture of others sparks is music to my sensors!!!

Those are pretty awesome.

Seeking the Following:

- CW Brawl

- Earthrise Runabout

- Earthrise Thrust

I would totally grab something like these. Very cool!

Twit and insta @lukeabarnett

Oh wow, thank you guys- I'm kind of overwhelmed

I'll keep working on them, and update them later to show you how they work out (they're still not perfect yet- edges need rounding off, etc). If I make enough, I might put something up here- or in the sale section. But they'll be small lots.

Ultra, I think I get what you mean. I wish I could visualise it. Do you have an example of the cutting tool you're thinking of?

They're very small though- I'm pretty sure scissors are my best bet. But I've realised I'm very impatient when cutting them. But found the smoother the corner (internal/external) is, the less likely it is the crack. I think that's probably what you've been trying to say XDD

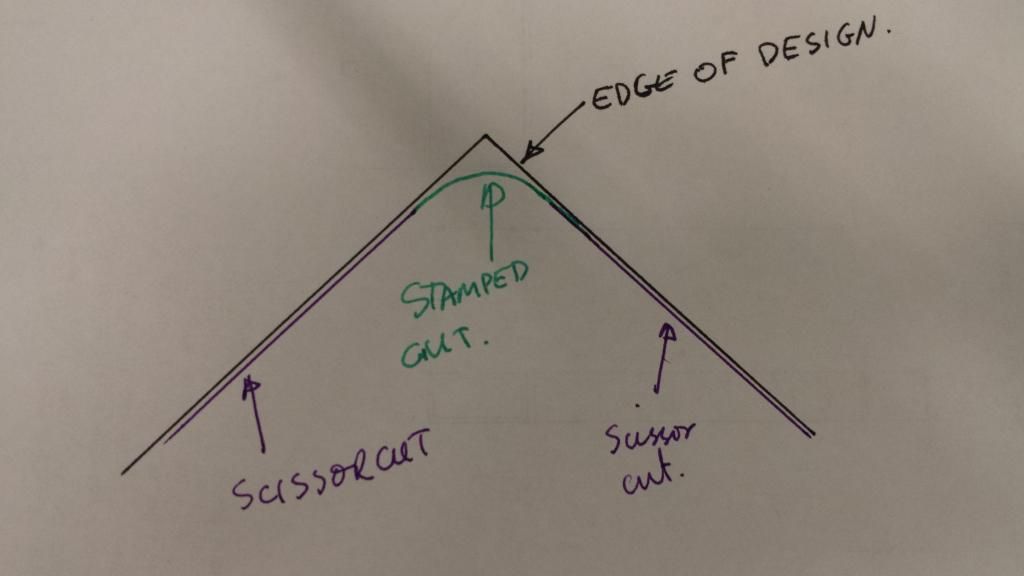

Here is a diagram showing the rough concept. the black line represents the pattern you are cutting around with the black text on the inside of the design..

the green is the first cut made with a punch or curved chisel (spindle roughing gouge) not what it's designed for but I imagine you can find similar tools that would perform a similar job. leatherwork and woodwork tools are very sharp and can be found in many different profiles.

you then cut up to that initial cut with scissors or a sharp blade, however you normally cut. the advantage is the corner is already done so you can cut straight lines right up to your pre-existing corner cut. The caveat is I have no idea how the material you're using will respond to being punched through in this manner. It should be OK on a solid cutting mat, I'm gueesing