3d printing systems held the promotion that i missed out on. I have contacted them and although they were apologetic that i missed out ireally dont think they cared much. The promotion was an american 'black friday' style sale. 100's of people interested, only a couple [less than 10] units up for grabs.

Why you would go out of your way to aggravate, infuriate and alienate you potential customer base, defies logic...

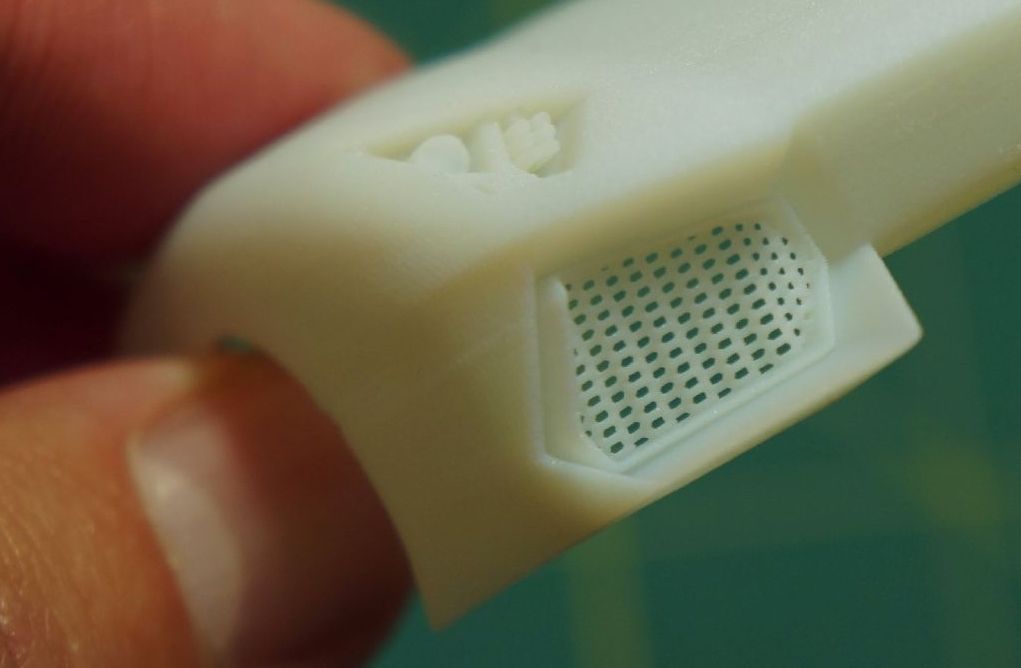

that being said, The UP plus printer [available from 3d printing systems au/nz] is probably the best hobbyist 3D printer on the market, but it is still just a little expensive. The up plus has a metal chassis, and is very sturdy. The up mini has a smaller build envelope

And yes you could design a weapon/sword/mace in sketchup, and then convert that into an STL file, send that to the printer and [these machines are slow!] it will build it for you. Awesome yes.

I have been closely following this technology since early 2005.

Originally Posted by Moddler FAQ

Reply With Quote

Reply With Quote