UPDATE 29/07/2016

So after my last "no shaking" method crashed and burned I modified the moulds, cutting extra air vents into the underperforming units.

You can see a lot more sprue on the parts, I also didn't clamp it as hard, this seems to have given a marginally better fill (but more flashing), You can't really see it in the photos but a LOT of surface bubbles are gone.

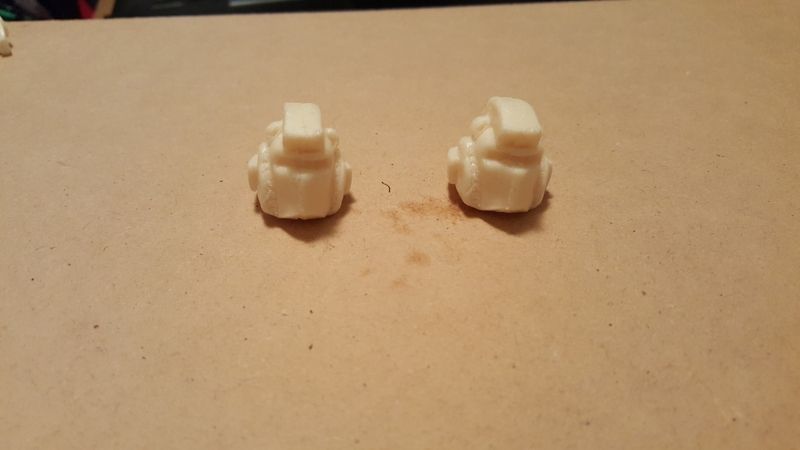

Side by side comparisons with V1 casts. Original on the left, new cast on the right.

This one was a pity with the air bubble in the middle. It will still be a day or two before I can sand (the extra gloss on the new casts will go away somewhat) otherwise it was a superior cast. The attachable detail however was a much better cast

The beginnings of an IDW Roller

Pity about the bubble in his face

The extra vents made a massive difference for the failed casts

For a bit of scale

Start of Emirate Xaaron

So all in all the quality of the resin has improved. I'm quicker and cleaner at pouring now so I spent more time mixing to make sure. But.....to eliminate the bubbles I'm going to need to cast under pressure. I think that will give a horrible result though as it will force the silicone to pucker (Because the silicone wasn't cast under pressure).

Reply With Quote

Reply With Quote